Why have your own milling and mixing equipment?

On-site feed production leads to independence from the compound feed industry and reduces total transport costs.

The experience of our customers also demonstrates the significantly improved feed intake, improved digestibility and lower mortality of animals.

If you want to be able to provide your pigs, cattle, chickens and other animals with quality, customized feed made from your own raw materials, Buschhoff is your reliable partner for milling and mixing systems.

Our benefits

- High level, reliable automation

- Excellent value for money thanks to the long service life of equipment

- Single level and neatly arranged construction

- Large batches for high performance and reduced dosing and mixing processes

- Reduction of costs by utilizing existing buildings

- Individual milling of feed components for particularly good feed structure

- Low maintenance and running costs

- High proportion of in-house production incl. the control providing excellent equipment quality and rapid supply of spare parts

You benifit from:

- Feed quality tailored for different animal species

- Use of your own resources

- Always fresh feed

- Full confidence in feed quality, recipe and ingredients

- Independence from the compound feed industry

- Improved usability of feed components

- Uniform feed mixtures

- Cheaper than purchased feed

- Reduced workload through automatic control

- A range of analysis options to optimise operations

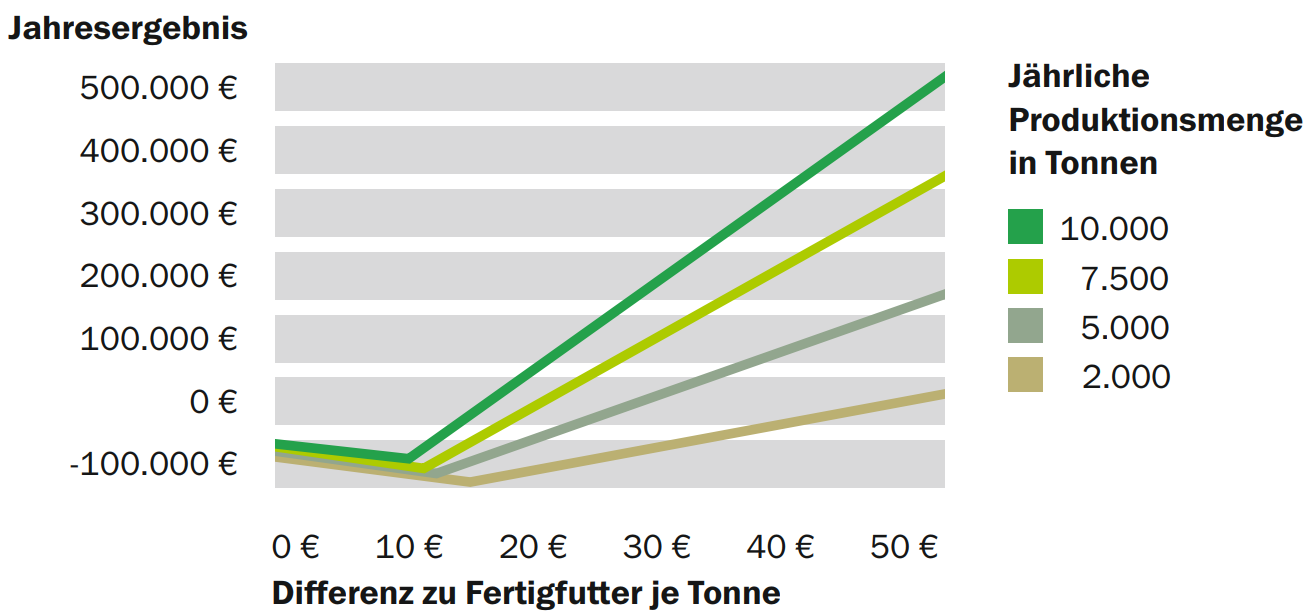

Profitability example of a 5 t/h Buschhoff feed mill

Milling technology

Mixing technology

Control engineering

Milling technology

Mixing technology

Additional equipment

Control engineering

Drum purifier type BTR

You benifit from:

- Efficient and economial cleaning before the milling process

- High performance due to big screen drum

- Slowly running screen drum for gentle cleaning

- Extremely compact and robust design

- Significant increase in feed quality

- Increased durability of the mills and the wear parts

- 0.75 kW gear motor direct drive

- Does not transfer any vibrations to the mill

- Various screen drums possible – according to type of grain

| Typ BTR | 300 | 500 | 650 S | 650 |

| Anzahl Siebe | 1 | 2 | ||

| Siebtrommel Q15 (t/h)* | 4 | 9 | 10 | 9 |

| Siebtrommel Q18 (t/h)* | 6 | 12 | 15 | 12 |

| Motor (kW) | 0,75 | |||

* Depending on grain

Industrial hammer mill type BHOS 500-1200 S

The industrial mills of the type BHOS 500 – 1200 (37 to 90 kW) are extremely robust and particularly powerful hammer mills, which allow to produce very different feed structures while also beeing highly energy efficient. This is achieved through the compact design, the extra large screen area, the low-wear hard metal hammers and the quick change system of the screens.

With a screen area of 0,65m² or 1m² the industrial mills have a particularly generously design per kW. This allows an even feed structure in combination with extremly high throughput rates.

All mills can optionally be equipped with a frequency converter in order to determine the rotor speed depending on the component or recipe and thus produce the desired feed structures.

The robust mill design with rotor bearings on both sides, the large number of reinforced hard metal hammers and Buschhoff’s decades of experience in mill construction make these mill types a real power pack for the various milling requirements.

| Typ BHOS | 500 | 600 | 1000 | 1200 |

| Antriebsleistung (kW) | 37 | 45 | 75 | 90 |

| Mahlleistung | bis 8 t/h | bis 9 t/h | bis 12 t/h | bis 14 t/h |

| Drehzahl (U/min) | 2900 | |||

| Zahl der Hartmetallhämmer | 40 | 104 | ||

| Anzahl Siebhälften | 1 | 2 | ||

| Gesamte Siebfläche (m²) | 0,65 | 1 | ||

Hammer mill type BHOS 150-300

You can rely on the performance of our blower-less millof the BHOS type when high capacity feed production is necessary and the feeding of grain to the mill via tubular screw conveyors or conveying spirals is provided

Whatever Buschhoff product suits your needs best: You will have a high-quality plant to provide fresh feed on a daily basis.

Your advantages at a glance

- Blower-less hammer mill with powerfull three-phase motors ranging from 11 to 22 kW

- Can be operated with either perforated or wire screens thanks to the quick-change system

- Reinforced hard metal hammers for a particularly long service life

| Typ BHOS | 150 | 200 | 250 | 300 |

| Antriebsleistung (kW) | 11,0 | 15,0 | 18,5 | 22,0 |

| Mahlleistung (kg/h) | 2300 | 2700 | 3000 | 4400 |

| Drehzahl (U/min) | 2900 | |||

| Zahl der Hartmetallhämmer | 24 | 32 | ||

| Gewicht (kg) ca. | 280 | 300 | 310 | 400 |

Performance data relates to 4 mm round hole screen and 14% grain humidity. Milling performance varies according to type of grain, humidity, screen type, residue.

DUO mill type BHOS DUO

Your advantages at a glance

- 2 different and independent screens

- Bi-directional rotation of the rotor

- Motor rating: 11 – 22 kW

- Maximum screen surface

- Special reinforced hard metal hammers

(Service life ca. 15.000 t)

You benifit from:

- Excellent throughput performance

- Flexibility of two seperate mills

- No manual change of the screen

- Better quality of the feed, through customization according to the needs of different species of livestock

| Typ BHOS DUO | 150 | 200 | 300 |

| Antriebsleistung (kW) | 11,0 | 15,0 | 22,0 |

| Mahlleistung Weizen 4mm Sieb (kg/h) | 2300 | 2700 | 4400 |

| Drehzahl (U/min) | 2900 | ||

| Zahl der Hartmetallhämmer | 24 | 32 | |

| Gewicht (kg) ca. | 290 | 310 | 410 |

Performance data relates to 4 mm round hole screen and 14% grain humidity. Milling performance varies according to type of grain, humidity, screen type, residue.

Hammer mill w. blower type BHS

Previous Next Plants with blower mill of the BHS type are the perfect choice for small to medium capacity feed production.

Because the blower mill can draw in the grain from storage containers wherever, it is perfectly applicable where easy and straight conveyance is impossible.

Your advantages at a glance

- Hammer mill for milling, dosing and mixing plants with a blower for multiple intake ports

- Mill casing with a wear lining

- Motor rating: 11,0 – 18,5 kW

- Reinforced hard metal hammers for a particularly long service life

- Available with various intake devices or a suction pipe

Typ BHS

150

200

250

Antriebsleistung (kW)

11,0

15,0

18,5

Mahlleistung (kg/h)

750

1000

1200

Drehzahl (U/min)

2900

Zahl der Hartmetallhämmer

12

Durchmesser Saug/Blasleitung (mm)

80/100

empfohlene Filterfläche (m²)

14

18

Maximaler Förderweg (m)

60

40

Gewicht (kg)

235

240

255

Autofilter type BAF

For a mill without blower we recommend the use of an autofilter.

The fully automatic Buschhoff-Autofilter performs three different tasks:

- Extraction of the bruised grain by suction from the mill which results in a very low proportion of fine meal in the bruised grain.

- It cools the bruised grain after the milling procedure Conserves ingredients and avoids condensate formation with its negative effects.

- It creates negative pressure throughout the whole plant and prevents the emission of dust.

Industrial mixer GM-WR

With a capacity of 4.8 – 9.6 t these feed mixers are especially suited for large businesses.

The Buschhoff GM series is of welded construction and therefore very robust.

Layouts and variants of this series, too, make for easy adaptation to customers individual requirements – optimal operation is assured.

The mixers deliver a mixing accuracy of 1:100.000 and use the well-proven forced mixing mode. The discharge performance goes up to 50 t/h. Intake augers enable a dust-free insertion of feed components, addition of up to 5% of feed oil is also possible.

Overview of technical details:

- Capacity of 4.8 – 9.6 t

- Mixing accuracy 1:100.000

- Mixing auger diameter 400 mm

- Multiple mixer outlets can be fitted

- Short mixing duration

- Oil addition of up to 5%

- Dust-free dosing

- Motor with 1.000 rpm

- Suitable for industrial use

- Optionally precise electronic weighing

Typ Mischer

GM1

GM2

GM3

Fassungsvermögen (m³)

8

12

16

Fassungsvermügen (t) bei SG 0,6 t

4,8

7,2

9,6

Elektromotor (kW)

5,5

7,5

11,0

Gesamthöhe H (mm)

4600

5250

6000

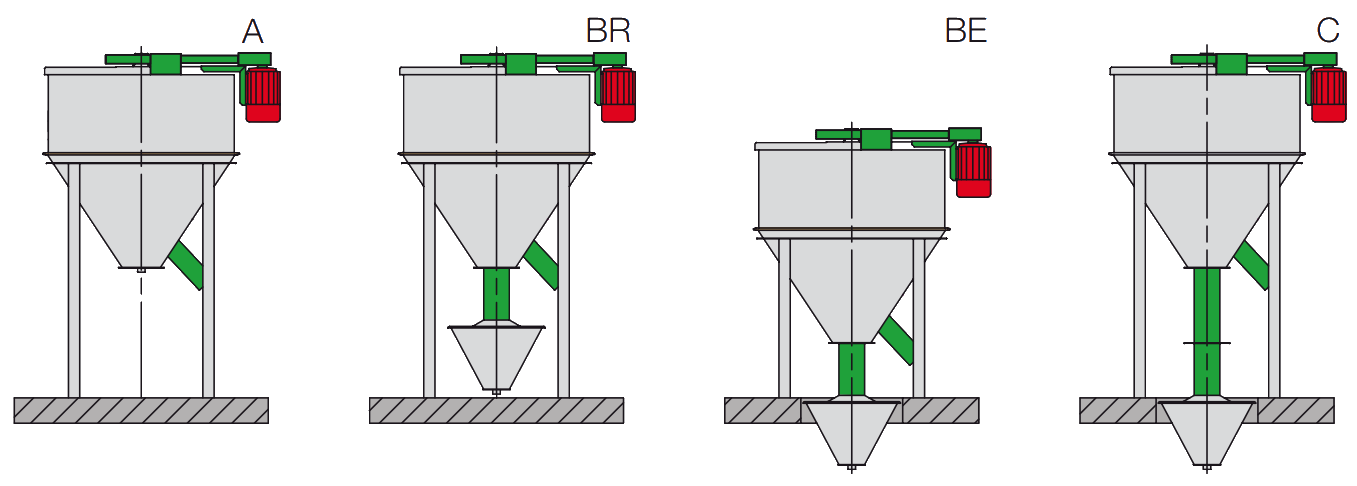

Feed mixer M-WR

The Buschhoff feed mixers are available in different designs and technical layouts. Their capacity is between 750 and 3.000 kg. They use the well-proven forced mixing mode, resulting in a mixing accuracy of 1:100.000. The large, slow-moving mixing auger makes for an efficient and fast mixing. Up to 5 % oil can be added without any problem.

Another advantage: The mixers with the WR layout can be fitted with intake augers up to a length of 4 m. Therefore a dust-free insertion of feed components is ensured.

Overview of technical details:

- Capacity 750 to 3.000 kg for a piled density of 0.6 t

- Mixing accuracy 1:100.000

- Mixing auger diameter 280 mm

- Electronic weighing

- Multiple mixer outlets can be fitted

- Oil addition of up to 5%

- Short mixing duration

- Optionally with central outlet (complete emptying)

- Optionally precise electronic weighing

Typ Mischer

M1

M2

M3

M4

M5

M6

Fassungsvermögen (kg) bei SG 0,6 t

750

1000

1400

1850

2550

3000

Mischdauer (min)

5-8

6-10

7-12

10-15

Elektromotor (kW)

bei Bauform A

3,0

4,0

5,5

bei Bauform B,C, und WR

3,0

4,0

5,5

7,5

Gesamthöhe H (mm)

bei Bauform BE

2145

2370

2770

3220

3845

4465

bei Bauform A, BR, C

2740

2965

3365

3815

4440

5006

bei Bauform WR

–

3050

3450

3900

4525

5106

Mineral dosing containers

The addition of valuable minerals and oils is critical to the health and growth of your animals.

Buschhoff systems enable automated and weighted dosage of these components in the feed mixture.

Depending on the type and quantity, powerful conveyors such as elevators, trough augers or spirals are used for the transport of minerals. Let us advise you as to which conveyor technology best suits your needs.

Depending on the task and dosing quantities, different mineral containers are available:

- Big-Bag brackets or agitator tanks for difficult flowing materials

- Re-weighing containers with their own weighing system can be used for very precise dosing

- Oil pumps are available in different performance classes:

20, 50 or 70 l/min; acid resistant on request

Pelleting

For pelleted feed, Buschhoff also provides the right solution. The services offered range from 2 – 20 t/h.

For the most part, we build these systems – including the milling and mixing equipment – as single level construction. This This saves costs, increases transparency and facilitates maintenance.

You benifit from:

- Powerful units ensure optimum pellet qualit

- The driving power of the press is 55 up to 350 kW

- All product contacting parts are made of stainless steel

- If required, a gentle pendulum bucket elevator conveys the pressed product into the cooler

- After pressing, the counterflow cooler prevents formation of condensate and ensures safe storage in the silo

Bagging units

You benifit from:

- Compact systems in different performance classes

- Either as a gross scale with direct dosing or net balance with pre-dosing for higher capacity requirements

- Easy control via PLC

- Available for different bags and closing systems

- Power range: 2 – 15 t/h

WIDOMIX Pro control

WIDOMIX PRO has been specially designed for larger milling and mixing plants and the demanding applications around this. Its clearly visualized complete control system manages all processes:

From overseeing milling and dosing, to mixing and afterwards feed transport to recording of components, formulations and the consumption of the entire system.

You benifit from:

- Full automated control allows the very simple production of customized feed

- Components, recipes, favourites and targets are easy to adjust and adaptable

- Fully automatic over-night plant operation (using cheaper off-peak electricity)

- Integrated control of the complete conveying and storage equipment

- Expansion of existing systems without programming is feasible (WINDOWS-based programming)

- Use, service and maintenance over the Interne

- Many business analyses possible, e.g. for optimizing operating processes

- Available in many languages: including German, English, Russian, French, Romanian, Polish

WIDOMIX 4.0

- Control cabinet with master switch and fuse group

- Control computer (fitted in control cabinet)

- Network and Internet compatible

- USB port for data transfer

- 100 components / 100 destinations

- 200 formulas arbitrarily programmable

- Error diagnostics

- Control for hammer mill

- Integrated load control

- Digital scale

- Control cabinet size 800 x 1200 x 300 mm

- Available in german and english

MOLARUS 4.0

Overview of technical details:

- MOLARUS computer for milling plants

- For mills with and without blower

- 10“ touch display, intuitive handling

- 50 components, 50 targets

- Process representation & plain text display

- Fully electronic load control

- External start & stop (by full-up indicator)

- Automatic idle switch-off

- Integrated load control for the hammer mill

- Operating hour counter

- Extensive data logging

- Remotely (also over the Internet) controlable

SIRUS

As a result of the fully electronic load control, the idling switch-off and the use of cheaper off-peak electricity up to 30% energy costscaused by the mill can be saved!

Overview of technical details:

- SIRUS computer for milling plants

- For mills with and without blower

- Fully electronic load control

- Automaticidle switch-off

- Integrated load control for the hammer mill

- Electronic amperemeter

- Operating hour counter

- External start

- External stop (by full-up indicator)

- 2 components, 2 targets

- Intuitive handling